PVC Wind Turbine Blades are becoming more and more common for homemade domestic wind turbines. The raw material, PVC pipe, is easy to find, relatively cheap, easy to work with, and performance is more than acceptable for a small basic wind turbine generator. PVC wind turbine blades can simply be bolted onto a Permanent Magnet Alternator or suitable Stepper Motor and you already have a basic wind turbine.

One of the most difficult parts of making your own wind turbine is producing suitable blades. Wind turbine blades go through enormous stresses and must be made to quite tight tolerances if they are to balance and not send destructive vibrations through your wind turbine.

Typically blades are carved from wood, but this is very time consuming, difficult, and requires a wide range of tools (saws, drills, sanders, clamps, work bench etc). (Click here to find out more about Making Wooden Wind Turbine Blades). Fortunately there is an alternative: PVC (or ABS) pipe cut to size. Best of all, if your wind turbine generator is damaged in a storm it is very cheap and quick to put together another set of turbine blades.

In strong winds the flexibility of the PVC blades is useful as it takes some of the energy out of the wind preventing the wind turbine generator from spinning too quickly and being damaged. Obviously you need to take care to ensure that the blades cannot bend back far enough to hit the wind turbine mast.

One Piece PVC Wind Turbine – Two Blades

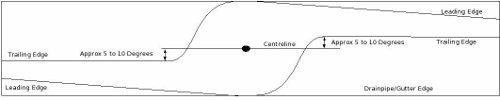

Individual wind turbine blades can be cut out of the pipe using a jigsaw or hacksaw blade, or a one-piece pair of blades can be made. Below is the original basic design for a one piece (two blade) PVC wind turbine propeller by Jeremy Parsons.

After further research and testing Jeremy felt that the above design was not the optimal configuration. He suggests now that the trailing edge needs to be moved away from the pipe centreline to improve the amount of lift (and therefore rotation) generated by the aerofoil. This modiified design is shown below.

Click here to visit Jeremy’s site and see the full size diagram of his turbine blade design together with the logic behind its new design.

Individual PVC Wind Turbine Blades

For larger wind turbine generators or if you just prefer to have three or more individual wind turbine blades, you need to create a hub to sit at the centre onto which the individual wind turbine blades can be attached. Blades can be screwed or bolted to a hub made from plywood or, for larger blades, a metal radiator fan from a car can be used with each of your PVC blades screwed onto a fan blade. The blades themselves can be most easily made by quartering the PVC pipe along its length, and making one turbine blade from each quarter.

The YourGreenDream website shows how to quickly quarter a PVC pipe and then shape each of those quarters into basic wind turbine blades as pictured below.

Increasing Efficiency of PVC Wind Turbine Blades

The video below shows how PVC wind turbine blades can be cut, filed, and sanded down to be more aerodynamic and therefore extract more energy from the wind hitting them:

Build Your Own Wind Turbine Generator

Click here to view a selection of photographs of PVC wind turbine blades in action.