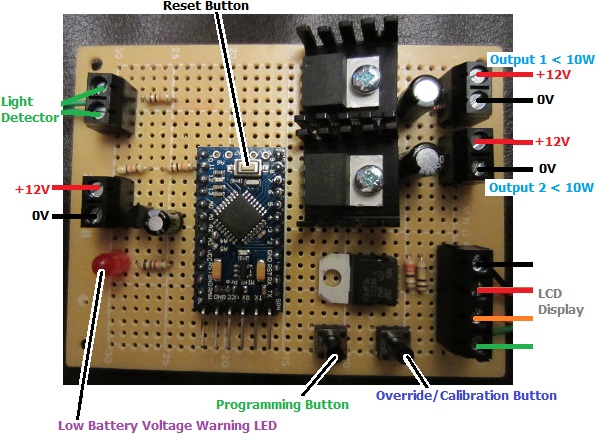

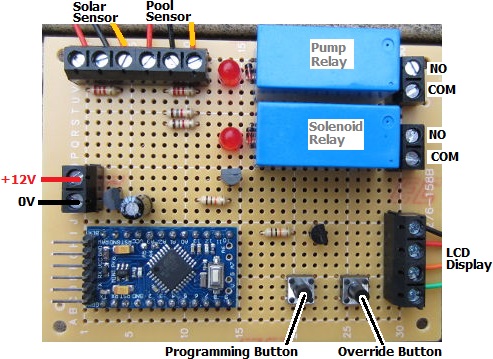

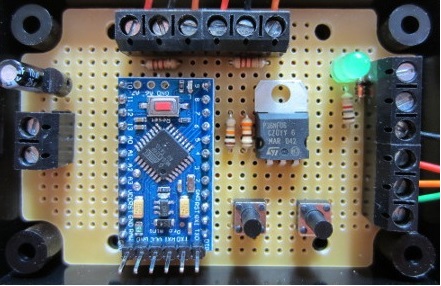

Pictured below is a controller we recently made for a wood fire cooker based heating circuit.

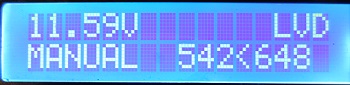

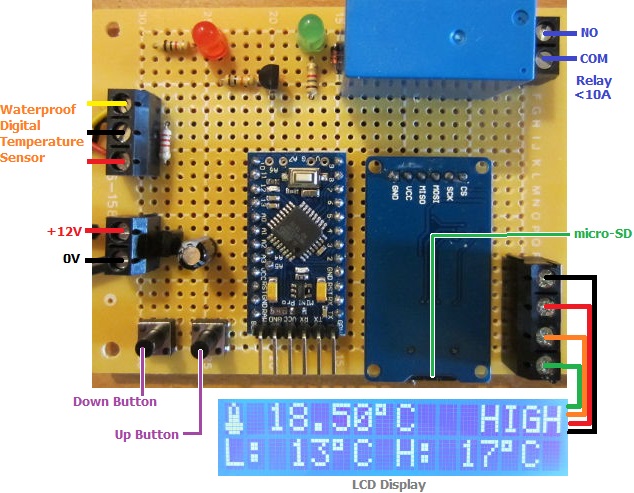

The controller itself is physically identical to our standard 2014 Solar Water Heating Pump controller with an LCD to display temperatures and system status and a couple of ds18b20 digital temperature sensors. However, it has been completely re-programmed for an alternative use.

The controller itself is physically identical to our standard 2014 Solar Water Heating Pump controller with an LCD to display temperatures and system status and a couple of ds18b20 digital temperature sensors. However, it has been completely re-programmed for an alternative use.

The customer has an Esse wood fired cooker with a 2.5kW domestic water circuit. This thermosyphon water heating circuit feeds a 140 litre thermal store in which a heat exchanger is used to heat up domestic hot water.

As there is some surplus heat over domestic hot water requirements, a pump is required to divert surplus heat to a panel radiator situated below the tank.

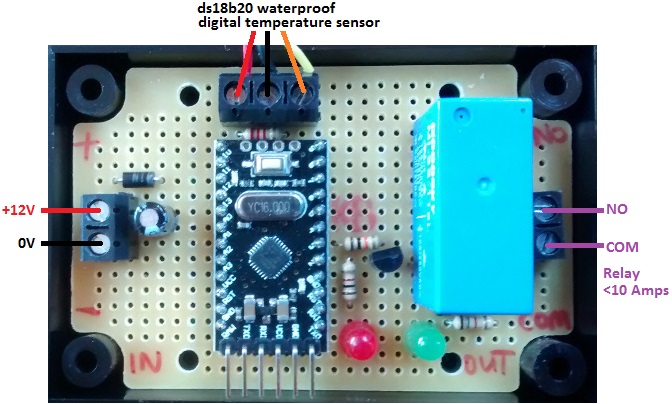

Two temperature sensors are to be fitted – one in the middle of the storage tank and the other on the return thermosyphon flow to the cooker.

The controller we put together for this system measures the temperature of the two sensors, and if both are found to be above user set values (for example, 80C for the tank and 45°C for the return flow), then the pump will be turned on to divert hot water to the radiator. When either of the two sensor temperature subsequently drops 2°C or more below the set values, the pump will be turned off sending hot water back into the storage tank.

If you need any type of water heating system controller, email neil@reuk.co.uk with details of your exact requirements.