Today we put together a special order low voltage disconnect (LVD) to be used with a product display case containing a digital photo frame.

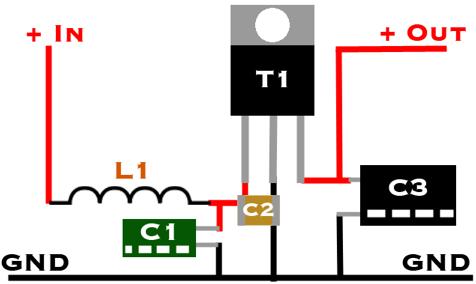

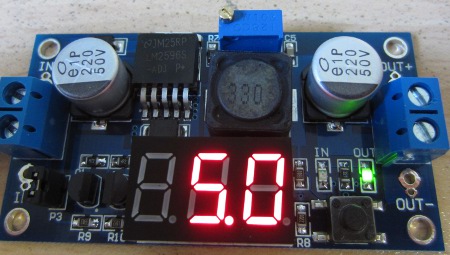

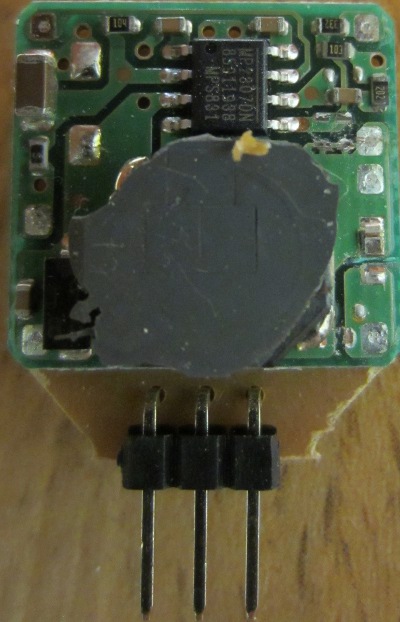

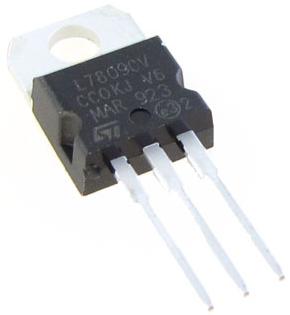

To make the case portable, instead of using the standard 5VDC power supply, 8 series connected high capacity C sized rechargeable cells have been fitted to give a 9.6V power supply which goes through a dc-dc voltage converter to get the required 5VDC to the photo frame.

Unfortunately when the voltage of the 8xC battery pack falls to 8.7V (when the battery pack is almost empty of charge), the photo frame software crashes and gets stuck in a constant reboot cycle due to not having enough power to restart.

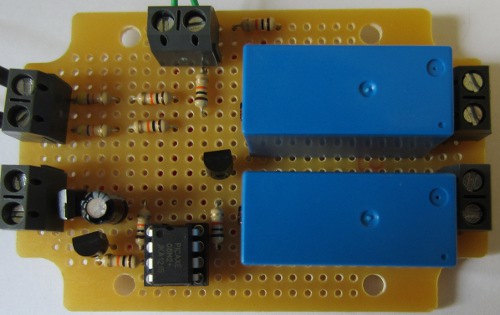

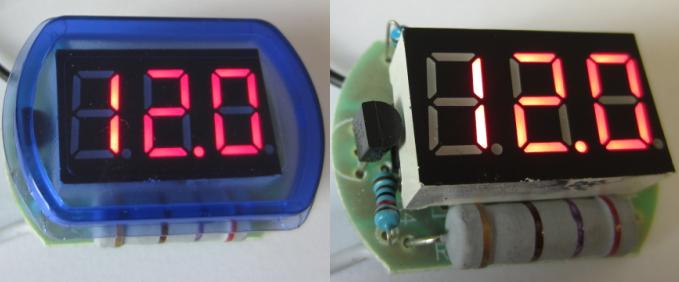

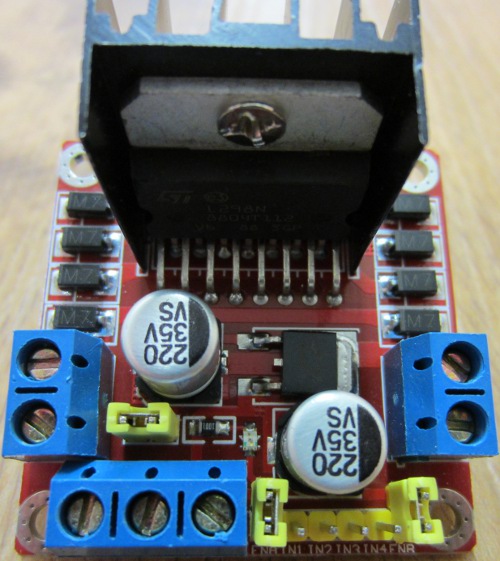

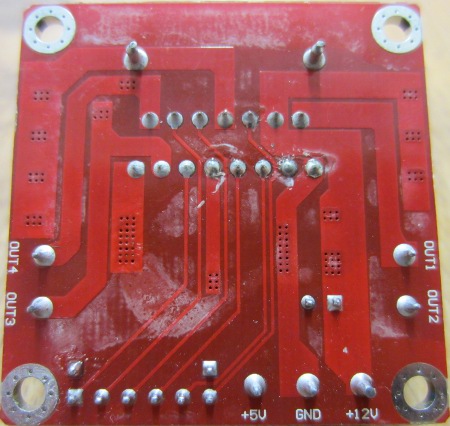

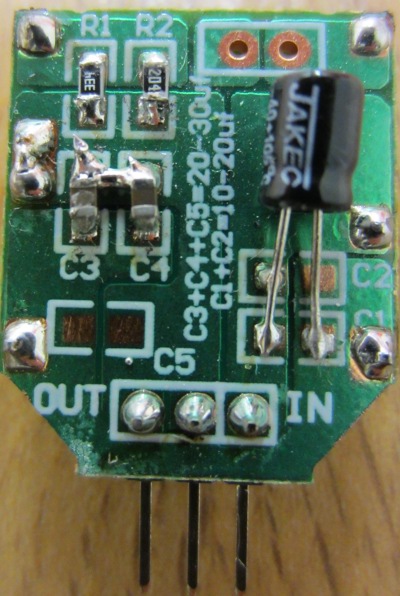

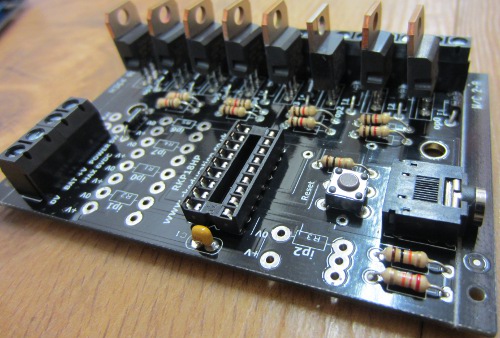

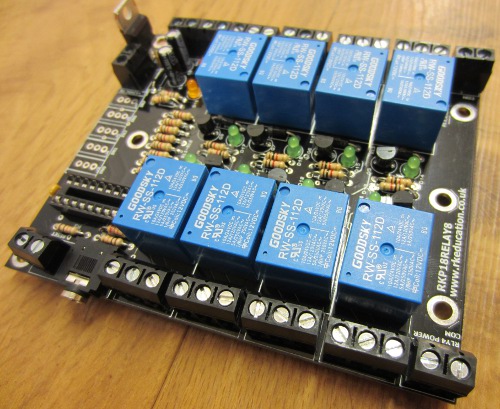

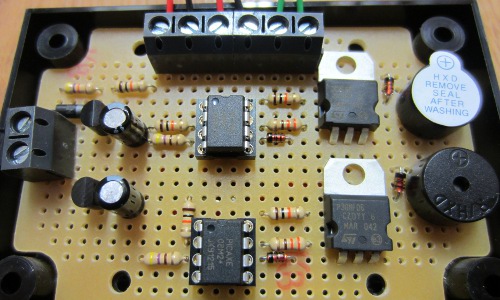

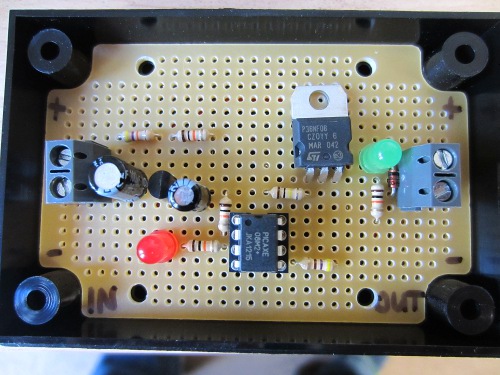

The low voltage disconnect we designed measures the voltage of the battery pack and if is more than 8.80V it outputs power to the voltage converter and photo frame. If the measured voltage falls below 8.80V, then the output is turned off and only turns back on again when the measured voltage is found to be greater than 9.20V.

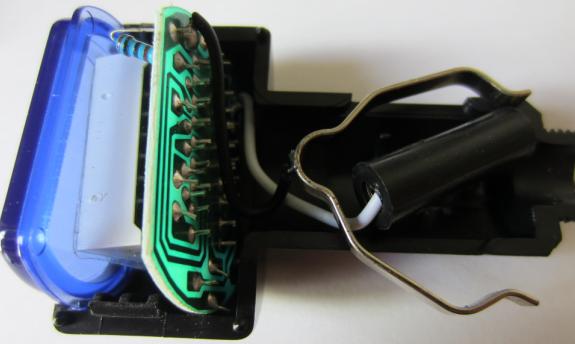

The display case is fitted with a standard off the shelf battery charger which takes a 12VDC input. An external 12VDC power supply can be plugged into the case to recharge the battery pack while at the same time powering the photo frame via the low voltage disconnect circuit causing the disconnect to be cancelled (since the measured voltage is now 12V) and the photo frame to restart.

When the 12VDC is supplied, the 8xC cells are automatically disconnected from their series circuit and connected individually in parallel to the battery charger for charging. When charging is complete, the 12VDC power supply can be disconnected, the battery pack voltage will be >9.20V, and so the frame will continue unaffected.

We sell our own automatic user programmable low voltage disconnect in the REUK Shop. If you have any special requirements which this product does not meet, let us know and we should be able to put something together for you.