We have just finished working on a new low voltage disconnect project for a customer who supplies batteries and power inverters to consumers. Quite often his customers make complaints that the batteries have failed after a relatively short period of time, but he had no way of knowing if there was a problem with the battery or (more likely) a problem with the way the battery has been used and cared for.

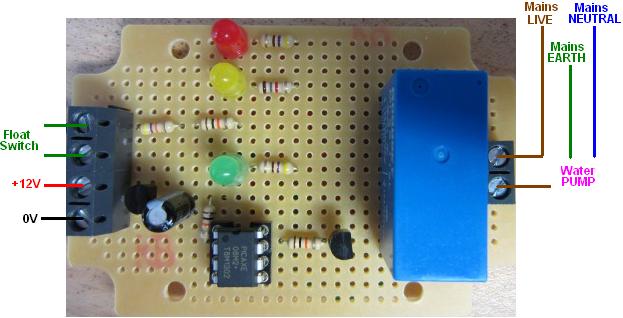

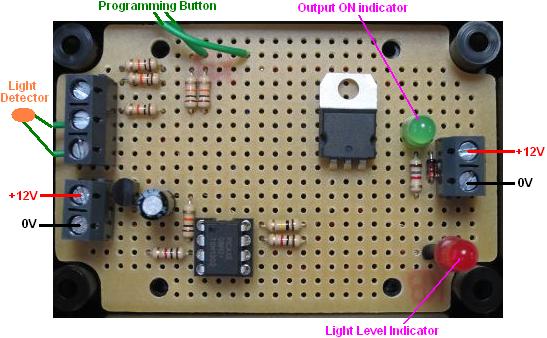

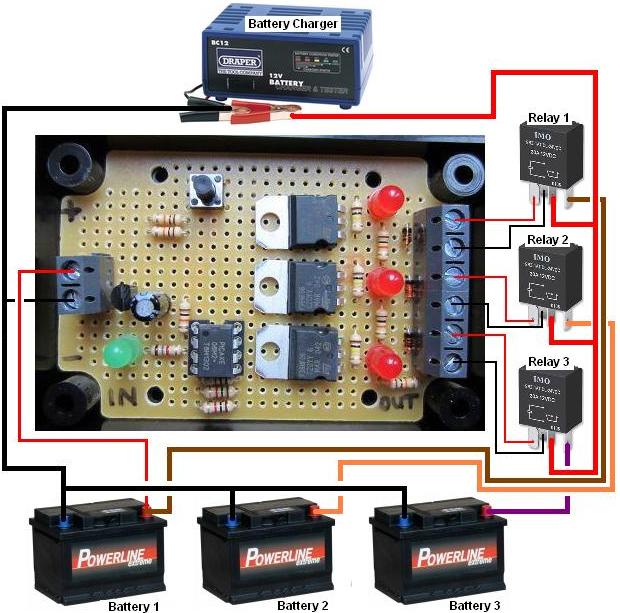

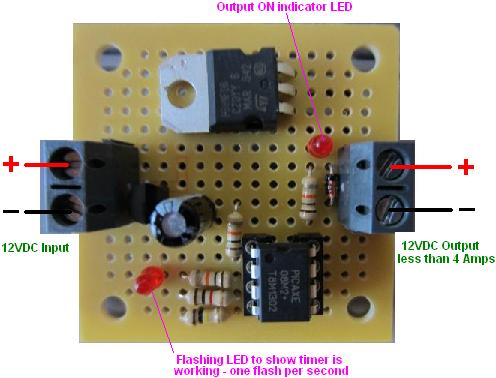

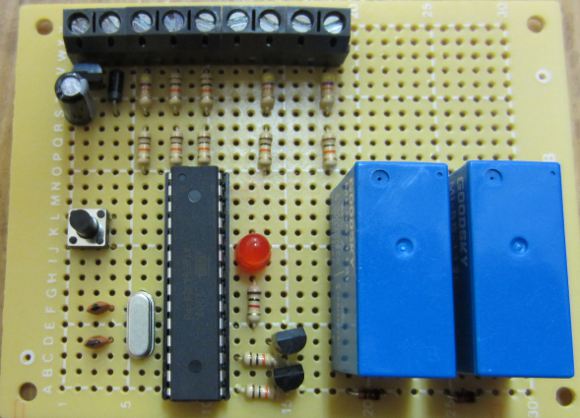

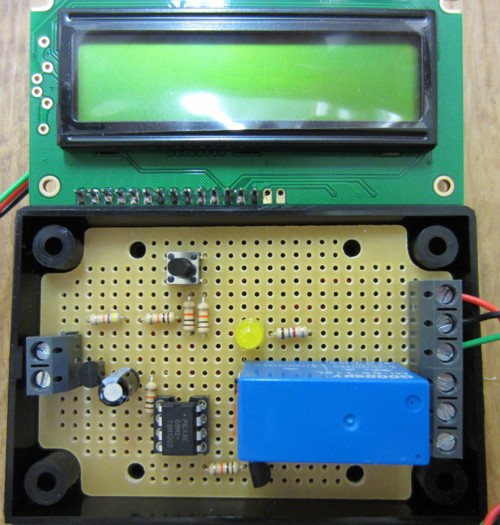

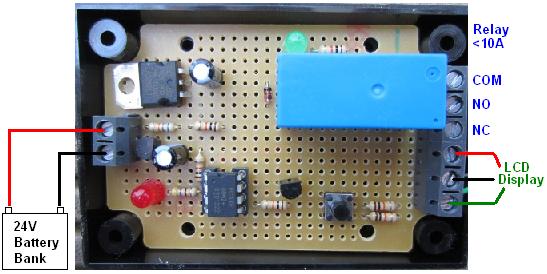

Pictured above is the low voltage disconnect with datalogger we made to solve this problem. The low voltage threshold at which the connected power inverter will be turned off, and the cancellation voltage at which it will be turned back on again can be set before installing the system. A low voltage of 22-24V is likely to be used and a cancellation of voltage of 24-26V for this 24V battery system.

Pictured above is the low voltage disconnect with datalogger we made to solve this problem. The low voltage threshold at which the connected power inverter will be turned off, and the cancellation voltage at which it will be turned back on again can be set before installing the system. A low voltage of 22-24V is likely to be used and a cancellation of voltage of 24-26V for this 24V battery system.

So that the treatment of the batteries can be assessed later, this controller has a built in datalogger. Every 12 hours it records the voltage measured on the connected batteries. Up to 200 data points can be stored in memory for a record of 100 days of activity. If more than 200 are collected then the earlier data points are over-written so that only the most recent 200 are stored.

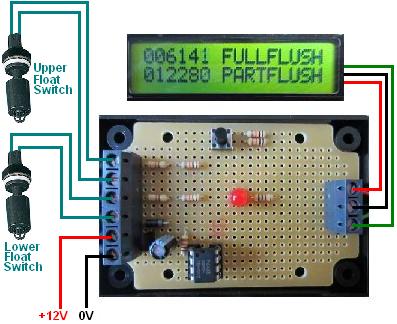

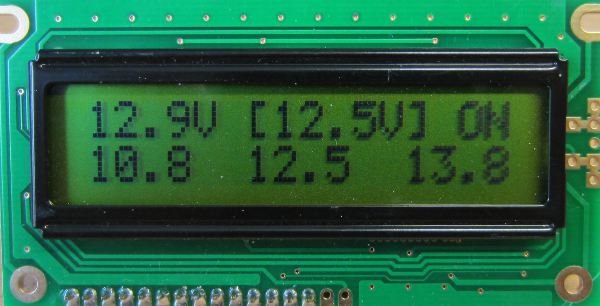

If/when the system is returned, an LCD display can be connected which enables the 200 data points to be stepped through from most recent to oldest, and a summary is also generated which displays how many times each voltage (from 1V to 35V) was recorded over the last 100 days. Using this data it is possible to see if the batteries were left uncharged for an extended period of time (very harmful to battery life), and how often they were run down to low charge levels (also bad for batteries).

If you need a low voltage disconnect and/or a datalogger, contact neil@reuk.co.uk with details of your specific requirements.