Today we put together a fail safe protection system for a well pump used to fill a header tank for a domestic water supply. This fail safe is designed to be connected in series with the existing pump controlling Stuart Turner float switch to cut the power to the pump if the header tank is about to overflow. If the primary float switch sticks or otherwise fails and does not turn off the pump when it should, the fail safe system will override it and turn off the pump.

The heavy duty MONO pump in this particular system is rated at 1hp (0.73kW) and pumps water up from from a well 15 metres below the header tank at a rate of 10 gallons per minute. Therefore a float switch failure and the subsequent flood of water overflowing the header tank and going through the house could be extremely serious and costly.

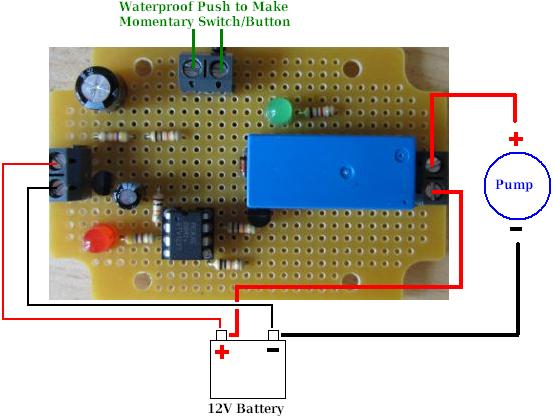

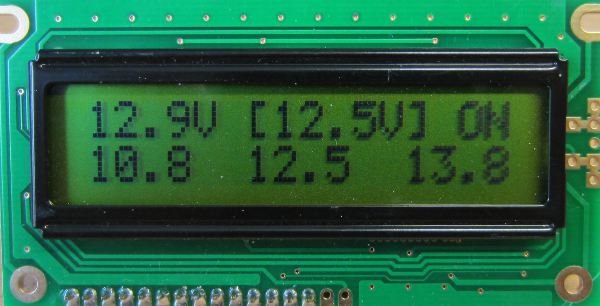

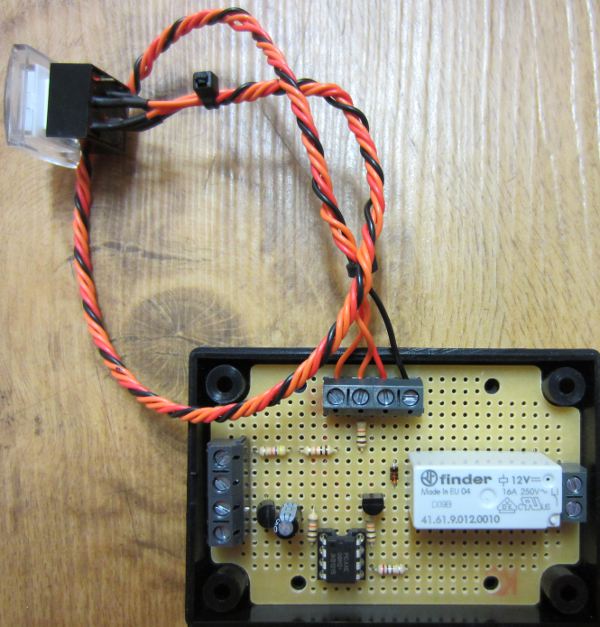

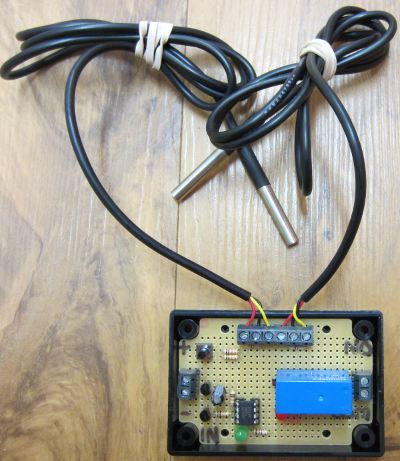

Pictured above is the solution we came up with. A secondary float switch is fitted into the header tank just above the existing float switch. In normal operation, this secondary float switch is closed which keeps a relay on our controller closed through which the mains live passes on its way to the existing primary float switch.

Pictured above is the solution we came up with. A secondary float switch is fitted into the header tank just above the existing float switch. In normal operation, this secondary float switch is closed which keeps a relay on our controller closed through which the mains live passes on its way to the existing primary float switch.

If the level of the water in the header tank reaches the secondary float switch, the float rises up which opens the switch. This causes the relay on our controller to open cutting the live connection to the primary float switch and therefore to the pump keeping it turned off.

We have added a button (pictured above) which under normal operation can be used to test the fail safe for peace of mind – pressing the button causes the relay to open and the LED in the button to light up for a few seconds.

If the fail safe is triggered by high water then the pump turns off and the LED in the button turns on to give a visual warning that something has gone wrong. The home owner must then check the header tank, remove any obstruction from the primary float switch, confirm that float switch is working reliably, and then press the button to manually reset the fail safe. There is no automatic reset of the fail safe as this would be far too risky – flood damage was averted and now manual intervention is a must.

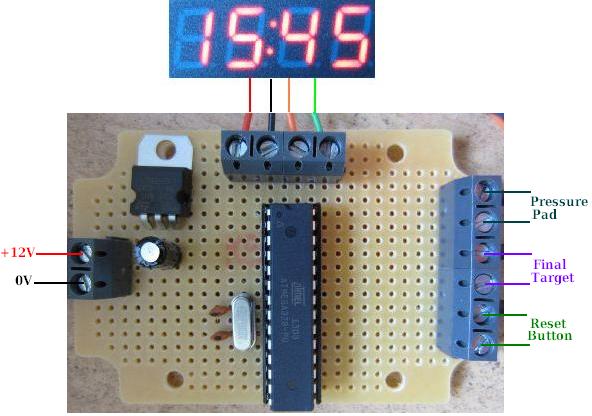

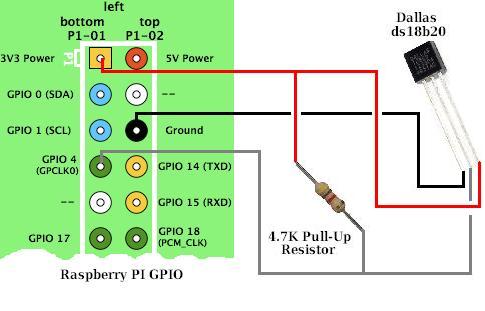

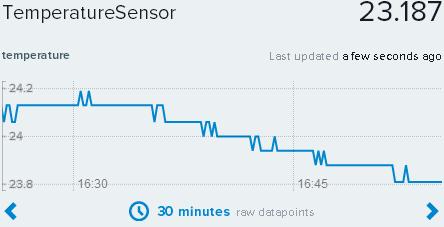

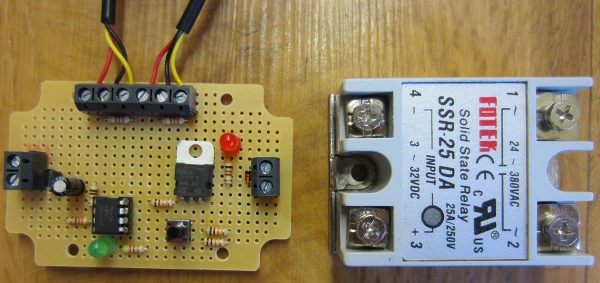

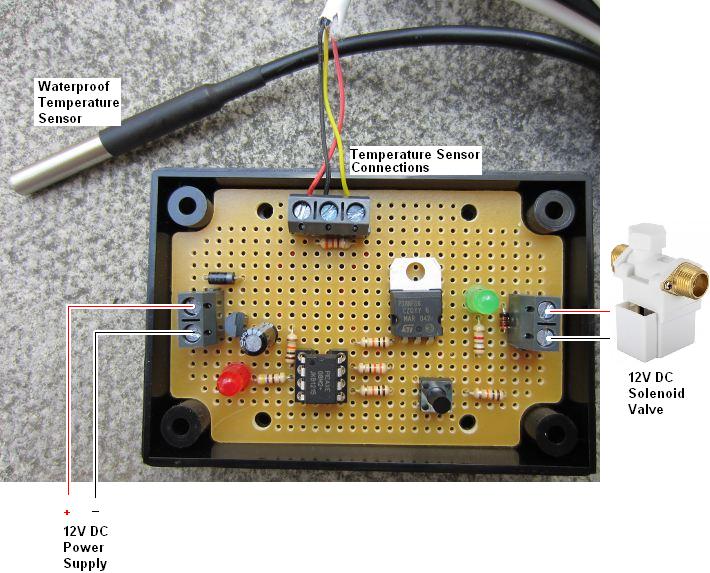

As it can take up to 0.75 seconds for the controller to get a reading from a DS18B20 sensor, and since sometimes digital sensors output spurious data, there have been some modifications made to the logic which decides when the circulation pump should be turned on and off, but all the original functionality of the 2013 controller has been retained.

As it can take up to 0.75 seconds for the controller to get a reading from a DS18B20 sensor, and since sometimes digital sensors output spurious data, there have been some modifications made to the logic which decides when the circulation pump should be turned on and off, but all the original functionality of the 2013 controller has been retained.