Having a reliable system to pump out a sump pit is essential as mistakes and failures can lead to serious flooding and enormous expense. In our article Sump Pump Control System we introduced a selection of electronic solutions to the following problems:

1) Identifying when the sump pit is full and automatically turning on the pump.

2) Stopping the pump before the sump pit is empty so that the pump stays submerged (increasing its lifetime) and it never runs dry.

3) Not letting the pump turn on and off repeatedly (multiswitching) or excessively frequently.

One common comment from some of our site visitors is that they have very limited electronics knowledge and no soldering experience – therefore our sample circuit designs are no practical use to them. What they really want is a system which is foolproof to put together, requires no special tools or experience, and is easy to troubleshoot and maintain. In this article we will present a new sump pump control system which is economical and simple to build, very reliable, has few component parts, no electronics, and is easy to maintain.

Sump Pump Control System Design

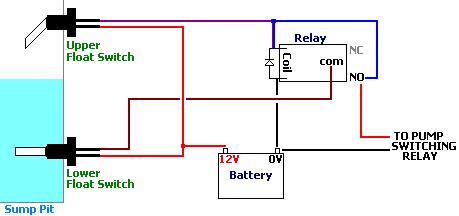

The system illustrated above is designed to work as follows: There are two float switches, one fixed high in the sump, and one positioned just above the height of the pump’s water intake near the bottom of the sump. The upper float switch turns on the pump when the water reaches the high point. The lower float switch turns it off again when the water has been pumped out of the sump pit.

How Does the System Work

When the sump pit has water in it the lower float switch (LFS) is closed (i.e. floating horizontally). As the water level in the pit rises, it eventually reaches the upper float switch (UFS) lifting that float to the horizontal and closing its switch.

With the UFS closed, current flows from the 12V terminal of the battery to the relay coil energising it. This connects the COM and NO terminals of the relay allowing current to flow along a second path from the battery to the relay coil:

Therefore, once the relay has been energised, it will latch – i.e. remain energised – as long as the LFS remains closed (which it will as long as it remains under water). As the pump empties the water from the sump pit, the pump stays on even when the UFS stops floating and until the water finally gets down to the level of the LFS. When the water level goes below the LFS, it breaks the connection between the relay coil and the 12V terminal of the battery, and so the relay switch will open turning off the pump.

Connecting the Pump

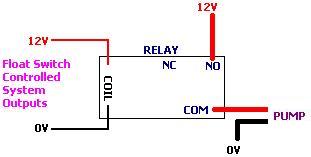

The output from the above described system comprises one 0V and one 12V connection. These are to be connected to the coil of a second relay which will physically switch the pump.

If it is a 12V pump you simply connect the COM of the second relay to the battery 12V terminal, the NOof the second relay to the pump’s 12V connection, and the 0V terminal of the battery directly to the 0V connection of the pump.

If this is a mains powered pump the final connections must be made by a qualified electrician with everything insulated and earthed according to regulations. (The thick red lines in the above schematic correspond to the mains live, and the thick black lines to the mains neutral.)

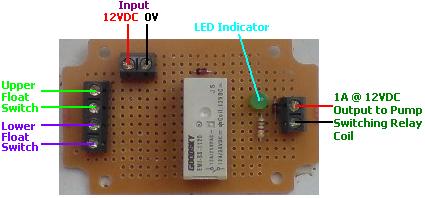

Sump Pump Control Circuit Board

Pictured below is a small board put together following the main schematic shown at this beginning of this article. The only added component is an LED (with current limiting resistor) to give a visual indication of when the pump is on. With a board such as this it is possible to simply screw the float switches into the screw-in terminal connectors and keep everything tidy.

If you would like to have a board such as the one pictured above put together, please contact neil@reuk.co.uk with details of your exact requirements.

Further Uses for this System Design

This design is also useful in many irrigation, rainwater toilet flushing, and rainwater collection systems, particularly in remote locations where reliability and ease of maintenance are essential.

NEW – Click here to read our article Simple Well Pump Controller in which we modify this system so that it can be used to automatically fill (rather than empty) a tank.

Acknowledgements and Thanks

Many thanks to Nyge for his hard work and vital contributions to this new pump control system.